8th May, 2024

In the construction industry, people have always been striving for innovation. Over time, technology has completely changed our attitude towards building materials – both what we think about them and how we use them. Among all these new options, steel is one of the most dependable ones; this material can do anything! Its versatility alone makes it indispensable in modern constructions but its strength also contributes greatly to their success.

Kay2 Xenox is a pioneer in this field, constantly coming up with new ways to use metals like never before seen, thanks to our state-of-the-art technology. We revolutionise buildings from start to completion by offering high-quality steel solutions for construction. Let’s go through some specific innovations that Kay2 Xenox offers to reshape the foundations of construction materials.

Technology has changed everything about how we plan, design and build structures today – it’s been truly game-changing! With machines doing most things that workers do manually, tasks get completed faster and more efficiently now than ever before. With digitalization taking over everything related to architecting or engineering: you can now visualise every little detail accurately!

Steel has become a popular choice because of its many amazing properties that make creative solutions possible in constructing buildings. Steelwork has been transformed by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). Once deemed impossible, experts can now design and construct intricate buildings which push the limits of what is possible with architecture.

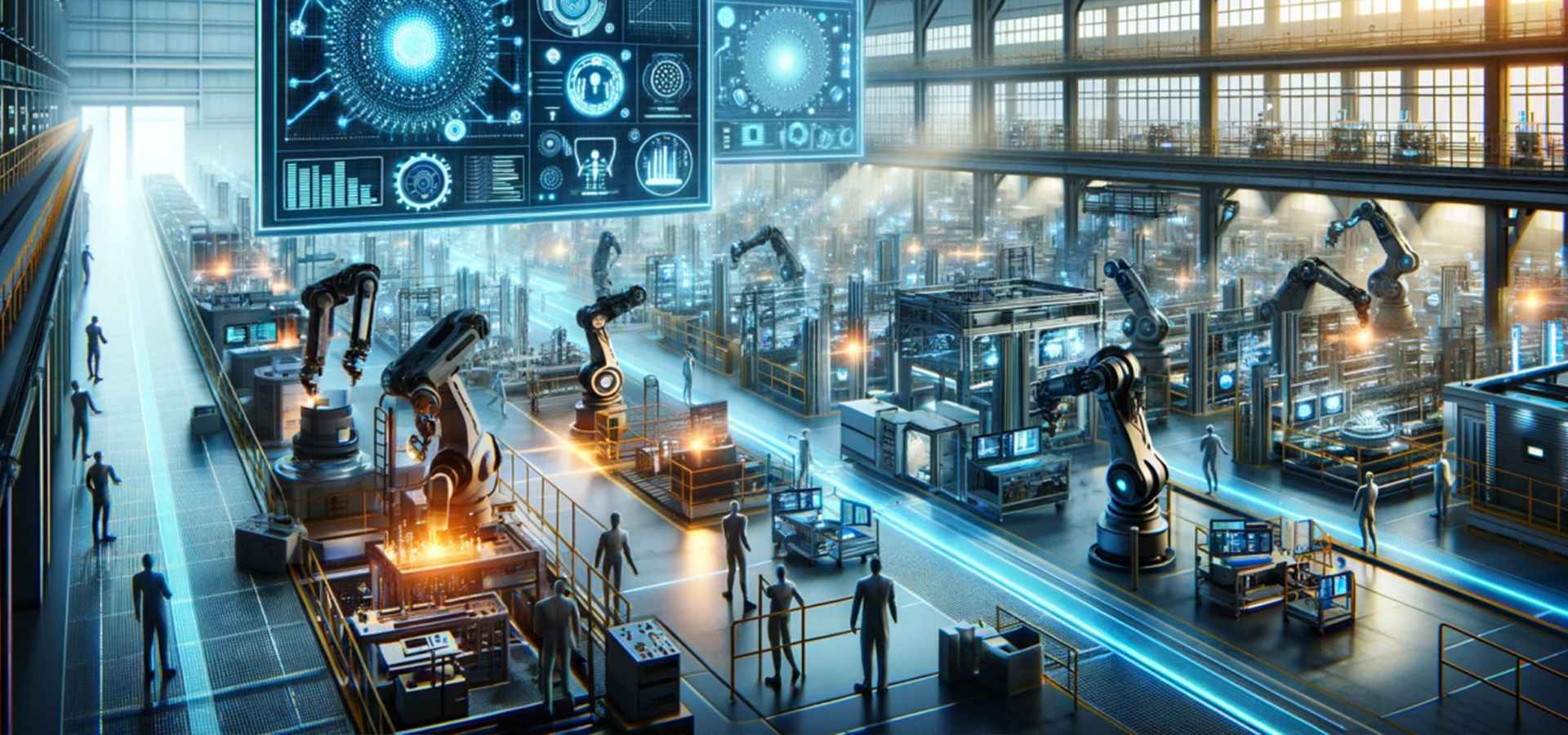

Modern construction would not be possible without embracing technology as the driving force. Through technology, the manufacturing process becomes faster while maintaining higher quality standards thanks to robotics and automation.

In modern steel fabrication factories, robots are a must-have as they can deal with raw materials, cutting, welding and assembling steel components faster than any human being can. At Kay2 Xenox, automated machines like these robotic arms ensure consistency of quality as well as reduce errors made by workers, hence speeding up projects.

From large-scale structural beam production or complex architectural element manufacturing, there is no other process of achieving such precision levels and reliability in steel building solutions than robotics.

In a time marked with environmental awareness, people have considered sustainability a major factor in the construction sector. Steel is a sustainable building material as it can be recycled. However, this can be made even more environmentally friendly through new techniques that optimize the use of materials and reduce energy consumption.

At Kay2 Xenox, we work towards manufacturing sustainable construction materials. We do this by adopting measures like using water-based coatings which are safe for the environment and following energy-efficient manufacturing methods that not only save power but also extend the life span of the products.

Workers have been given precision tools for fabricating steel by computer numerical control (CNC) machines. Digital designs are translated by these machines into exact production instructions to allow complex cuts, bends and finishes with little intervention from humans. Consistency across batches during production is guaranteed through CNC technology thereby making sure workers concentrate on higher-level tasks like quality control and innovation.

In steel fabrication, Kay2 Xenox CNC machines empower employees with precision tools that guarantee uniformity and accuracy. Such equipment converts digital designs into physical objects without any interruptions, thus maximising production processes while minimising wastage through efficient workflows and maintaining top-notch quality standards.

AI has changed the game for the construction materials industry, completely altering how they are made, used and improved. Artificial Intelligence uses algorithms to go through huge amounts of data which helps in understanding the properties of different materials thereby enabling researchers and developers to come up with stronger, long-lasting and sustainable building components.

Additionally, machine learning allows us to predict how these things will behave under various circumstances thus leading to their creation being more efficient than before.

The role of digitisation is huge in the construction materials industry. It transforms everything about how we develop, produce and use our stuff. At Kay2 Xenox, we see this as the basis for successful business and do anything that will make us work better together or faster than anyone else. With things like BIM software and CAD systems, architects can accurately bring their creative ideas to life thanks to our precision engineering skills.

Another great thing about digitization is that it helps people collaborate more easily when they’re using different advanced materials during a project. For example, if somebody needs some information on how something performs in real-time – all they have to do is ask us!

Right now there’s no denying how much technology has changed what we’re able to do with construction materials. We’ve always been one step ahead when it comes to finding new ways of working with steel solutions at Kay2 Xenox. Our commitment towards being excellent while still caring about sustainability means that our customers can trust that their cement will bond firmly together and foundations will become stronger than ever before, while having protection against earthquakes, fires, floods, rust, etc.

Kay2 Xenox goes beyond the limits of traditional methods in the construction industry by providing a wide variety of modern building solutions that are flexible enough to adapt to changing architectural trends. Be part of this revolution by embracing steel building solutions from Kay2 Xenox; where creativity meets perfection.